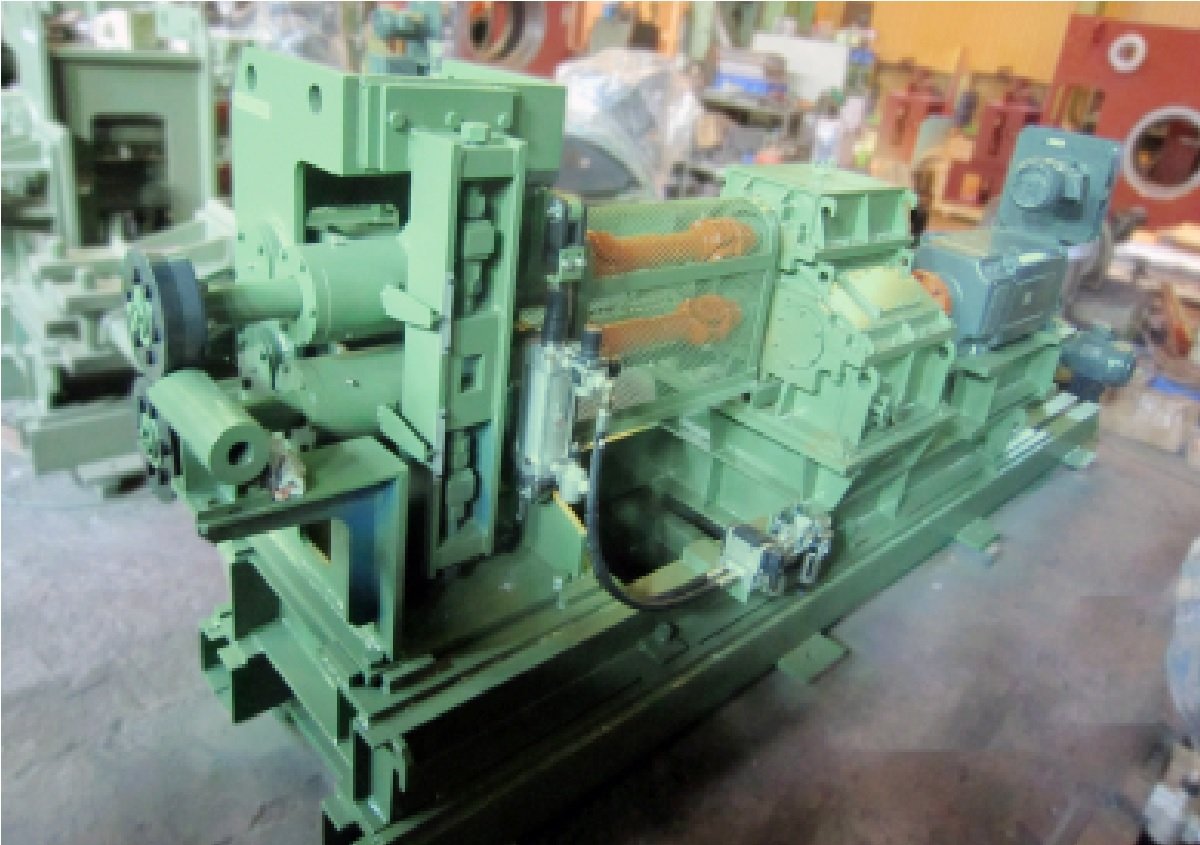

Quenching System

The Quenching System is a critical component in steel production, responsible for rapid cooling of TMT bars to achieve the desired mechanical properties. Flexii Steel’s advanced Quenching Systems ensure uniform cooling, enhanced strength, and superior metallurgical quality.

Equipped with precise water flow control and optimized cooling mechanisms, our Quenching Systems provide excellent temperature regulation, preventing cracks, warping, and inconsistencies in steel products.