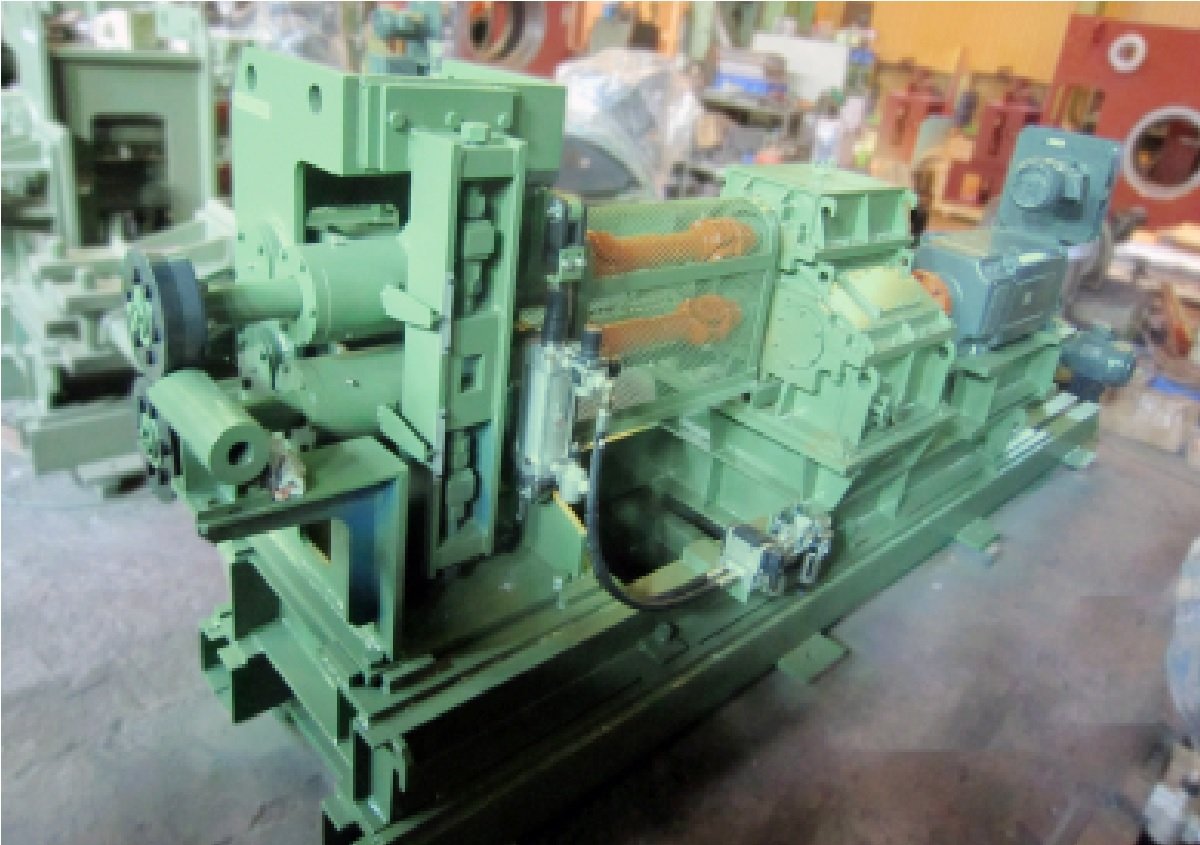

Automatic Cooling Beds

At Flexii Steel Rolling Mill Consultant, we deliver advanced Automatic Cooling Bed systems designed to handle, cool, and transport rolled products efficiently after hot rolling. Cooling beds are a crucial part of the rolling mill line, ensuring proper material handling and uniform cooling to maintain product straightness, metallurgical properties, and surface quality.

Our automatic cooling beds are engineered for high performance, durability, and seamless integration with your rolling mill operations.